Why do wheels balance?

Wheel balancing: what is it and why is it necessary?

Are you interested in what wheel balancing is, why it is needed, and how often it should be done? In this article we will talk in detail about this type of maintenance and its impact on the operating condition of the car.

Let's start with the fact that the balancing procedure was developed relatively recently, and many car owners quite often neglect it. They do this completely unreasonably, since in this case saving time and money can lead to disastrous consequences.

What is wheel balancing

The term balancing refers to the maximum possible, uniform distribution of the wheel mass relative to its axis. This correct arrangement allows you to significantly reduce the presence of vibration when the car is moving, and also eliminates early wear of the wheel bearing and car tires.

In simple terms, well-balanced wheels ensure a comfortable ride on any road. The car has excellent grip on the road surface and handles well at any speed.

No extraneous vibration is felt in the cabin, and the smooth running has a positive effect on the car’s suspension and the service life of the tires. Tire wear occurs evenly on each side, the wheel does not deform or wear out in certain areas.

Why do you need wheel balancing?

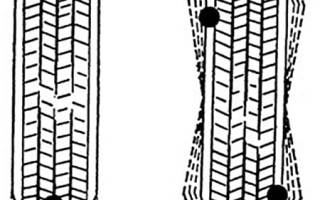

Static and dynamic wheel imbalance

As already mentioned, wheel balancing is needed to evenly distribute the mass of the wheel relative to its axis or, in other words, to eliminate imbalance. Experts divide wheel imbalance into two types:

- Statistical. The center of gravity shifts along the axis, resulting in an uneven distribution of the wheel mass along its length.

- Dynamic . This is when the axis of inertia does not coincide with the axis of rotation. In this case, the intersection of the axes occurs at an angle, which leads to uneven distribution of the mass in width.

The existing imbalance can be determined visually by lifting the car on a jack and spinning the wheel, as well as using special diagnostic equipment. The second option guarantees a more accurate result, and is provided as an available service at any tire shop or service station.

How to do wheel balancing

Wheel balancing machine

Before submitting the wheel to a computer stand for balancing, it is advisable to thoroughly wash and clean the tread and disc from dirt, small stones and sand. Their presence will not allow you to carry out the procedure correctly, and you will not get the expected result. Also, before starting balancing, the master must remove all previously installed balancing weights, regardless of their location.

Both front and rear wheels need to be regularly balanced. You should not single out only the leading pair, hoping that the mechanical impact on the other two wheels is less. Uneven wear can appear on any of the four treads, which will entail the consequences already described above.

The wheel balancing procedure itself is carried out on a special balancing machine or stand. The principle of its operation is to install a wheel on a rotating cone, which is automatically controlled by a computer program. The latter determines the exact type of imbalance and indicates where it is necessary to install a special weight to level the center of gravity.

The average weight of a zinc or lead load ranges from five to sixty grams, and is set manually by the master. The specialist also selects a balancing weight option (adhesive or padded), which is used in accordance with the type of wheel rim.

A modern method of computer diagnostics and balancing allows us to identify the slightest aspects of axial displacement that are invisible to the human eye. And it makes it possible to optimally correct the existing situation, which negatively affects the overall technical condition of the car.

On average, the wheel balancing process takes 40-60 minutes. The service can be ordered individually at a tire shop, or at a comprehensive service station. And the result of the quality of the work performed can be seen already at a speed of 60-70 kilometers per hour, on the first trip to the road.

Read also : How to properly store tires all seasons.

How often should you have your wheels balanced?

According to the rules, this maintenance is recommended to be carried out every 5 thousand kilometers of vehicle mileage. The optimal period will ensure minimal tire wear in case of imbalance, and it will be possible to get by with standard balancing rather than buying and replacing new wheels.

Balancing is required in the following cases:

- After a seasonal or regular tire change.

- If the car gets into a deep road hole or pothole.

- When a wheel hits a curb.

- After repairing one or more wheels.

- If vibration is detected in the cabin.

- When hitting the steering wheel at speeds over sixty kilometers per hour.

Each of the above factors should be a reason to urgently contact specialists. A quick response will prevent rapid wear of individual parts, and will ensure your safety on the road at any speed.

Do-it-yourself wheel balancing

A huge number of modern service stations allow you to quickly and easily carry out balancing at any time convenient for this. But for emergency situations, when tire fitting is not available, we will give an example of how this can be done with your own hands using balancing weights, which are sold in any car store.

In this case, you will need a jack, a wrench and a hammer. You need to lift one side of the car, turn off the gear (if the wheel with an imbalance is driving), and loosen the fastening nuts.

Without removing the disc from the hub, you need to spin the wheel to the left and wait for it to come to a complete stop. Mark its top point with a marker or chalk. Next, spin the disk to the right and also set the top mark. Thirty gram weights are placed opposite each mark.

Subsequent unwinding can be carried out in any direction, and at the moment of stopping the load will be at the bottom. This place will mark the lower balancing point. The next action should be the subsequent rotation of the disk and the displacement of the loads in directions opposite to each other. This procedure will cause the wheel to stop in different positions, which will indicate the optimal possible balance.

Of course, such adjustment cannot be compared with the exact data of computer stands and the verified actions of specialists. But for car enthusiasts who want to improve their technical skills, self-balancing will become an invaluable experience, and will help in the future to carefully monitor the level of paid service.

To summarize, we note once again that regular wheel balancing, carried out at least once a year, will allow you to protect important mechanical components of the vehicle from complex repairs and eliminate the purchase of expensive parts.

The necessary procedure will save your money and nerves. And you, as a practical and prudent driver, will get maximum pleasure from a good ride and can guarantee yourself optimal safety during high-speed driving.

Read also : Steering wheel vibration at speeds of 100-120 km/h - the main reasons.

Video on the topic

Reasons for the need for wheel balancing

It happens that an accident is a consequence of the improper functioning of its components and assemblies. One of the reasons may be that the wheels were not balanced on time, which affects the vehicle's handling. Failure to do so in a timely manner will make it difficult to control the vehicle and increase the likelihood of tragic accidents on the road. It is extremely important to understand why wheel balancing is needed and what causes problems associated with imbalance in order to promptly prevent difficulties that arise while driving a car.

What is wheel balancing and why is it needed?

The essence of wheel balancing is to distribute the mass of all the component elements of the wheel as evenly as possible relative to the axis of its rotation, i.e. balance them. The need for balancing is explained by a whole range of reasons:

- vehicle controllability is significantly improved and road maneuvers are performed normally;

- the service life of the vehicle chassis is significantly extended;

- traffic safety is ensured for all its participants.

How and when can you understand that it is necessary to balance the wheels?

It is important for drivers to know not only why wheel balancing is needed, but also how often it needs to be done. A similar need may arise if you are planning a long, long trip. You should check how well everything is balanced if you switch from summer to winter tires.

It is important to do balancing when you need to replace a wheel after a puncture or wheel failure. Experienced car enthusiasts will definitely note that uneven tire wear can lead to wear and tear of components, and it is simply impossible not to pay attention to this factor, because “bald” tires are a potentially dangerous factor in causing accidents on the roads!

And if you feel that it is difficult to control the car, it is constantly being pulled to the side, the steering wheel has become wobbly, or additional vibrations have appeared while driving, then you should contact a tire shop to check the balance.

The main causes of wheel imbalance

Imbalance and significant loss of vehicle control can occur for a number of reasons. The first and one of the most important is the poor quality of the road surface: potholes, bumps, holes. At speed, the wheel becomes deformed, and if you drive for a long time on such a road surface, this can turn into a serious problem. These same shortcomings on the roads lead to the need for wheel alignment. The appearance of imbalance is influenced by driving over rough terrain in mud, extremely worn tires on the wheels, as well as an aggressive driving style, involving sharp braking and jerking.

Balancing stages

Step 1. The wheel is mounted on a special balancing machine strictly along the axis of rotation; special lead weights are hung on both sides of the disk.

Step 2. The wheel begins to spin, and during spinning on a special stand, the mechanic stops the wheel and changes the position of the weights, achieving its balancing along the central axis of symmetry. Modern electronic stands will help you achieve optimal results - the wheel will be balanced according to electronic indicators.

Final wheel balancing

Final balancing is the sequential removal of errors that arose during previous stages on a special finishing machine. It is carried out in conjunction with the assembly of running elements. Finish balancing determines how the car will move at high speed, using highly precise balancing parameters. The balancing results are displayed on a special stand, which guarantees safe long-term driving.

How do you know if balancing was unsuccessful?

If vibration persists at speed, the car pulls to the side, skidding increases and the impossibility of straight-line movement increases, then this indicates that there is a need for re-balancing.

Wheel balancing - what it is, why and how often it should be done

Car tires, despite their apparent simplicity, have many features and nuances. To achieve the best performance, it should be installed correctly. An important procedure is wheel balancing. It's worth figuring out what it is.

What is wheel balancing and why is it needed?

Balancing refers to the procedure for eliminating imbalances between the wheel, hub and other suspension elements. Since centrifugal forces act on the wheel rim together with the tire, it is necessary to carry out this work over a certain period of time.

Almost always, the geometric center of gravity of the wheel does not coincide with the axis of rotation. The reason is the heterogeneity of the elements, first of all we are talking about the irregular shape of the wheel rim, some imbalance of the tire. This leads to beating when moving and other unpleasant consequences.

The first attempts to balance wheels were made in the 30-40s of the last century. Then motor sportsmen tried to pour water into tire inner tubes, sometimes they used sand and other bulk substances. But it soon became clear that such auto-balancing is useless, since the balancing substance is located at the farthest point of the circle. That is, balancing simply does not happen.

The first balancing, similar to the current one, was used in 1954. Moreover, they balanced the wheels of railway cars. Only after the successful use of welded weights on the railway, manufacturers of automobile wheels became interested in the technology. The first information about the use of balancing on cars dates back to 1959.

How to determine wheel imbalance - symptoms

It is important for the driver to understand whether it is necessary to balance the wheels, which will minimize difficulties with the suspension and also improve ride comfort. In general, it is recommended to check the parameter without even waiting for obvious signs of imbalance. Be sure to check and diagnose the disk in the following cases.

- If during operation there is a strong impact on the suspension. In this case, a situation may arise with damage to the wheel, and the tire may also be damaged. This all affects the balancing.

- During the seasonal tire change. Each tire has its own geometric features. When installing on a car, it is necessary to control the balance.

- It is advisable to check the parameter before traveling to regions where there are no service stations or services. Be sure to check the wheels for imbalance during off-road trophy raids.

- According to the recommendations of automakers, it is necessary to check the balancing every 10-15 thousand kilometers. If you drive a lot off-road, or prefer an aggressive driving style, it is better to reduce the period between checks by 2 times.

Don't forget about this work. The quality of the wheels is an important parameter that ensures traffic safety.

There are a number of signs that indicate the presence of an imbalance. Let's look at them in more detail, this may help in identifying the malfunction.

- Vibrations when moving. Moreover, the higher the speed, the stronger the vibrations; sometimes at high speeds they can disappear. This problem appears due to a shift in the center of gravity when moving relative to the axis of rotation. This creates vibrations.

- Shaking. A non-obvious sign, if the car shakes when driving on a flat road, you should think about an unscheduled balancing check.

- Impacts on the steering wheel when driving. Usually rhythmic and repetitive. Occurs when there is a large displacement of the mass relative to the axis. Sometimes impacts are mistaken for a suspension problem. Diagnostics must be carried out completely.

There are many signs, it is important to monitor them in a timely manner.

Do not confuse vibration when driving and when braking. If there is vibration during braking, the reason is not the wheel balance, but the wear of the brake pads.

What are the dangers of poor balance?

Sometimes drivers wonder whether wheel balancing is necessary or whether this work can be done without. In fact, imbalance can lead to a variety of problems.

- The most obvious effect of imbalance is deterioration of road grip. When vibration occurs, it breaks contact with the road surface. Depending on the situation, it can lead to loss of controllability and reduced braking efficiency. Since the contact patch is unstable, the risk of losing control of the vehicle increases on slippery roads.

- Vibration and shock place undesigned loads on the suspension. To understand the situation, an imbalance of 3 grams causes an impact on the suspension weighing 0.3 kg at each revolution, and there can be 600-800 such impacts per minute. Comparable to the same number of hammer blows on the suspension. Naturally, the wear of parts increases.

- Severe vibration loads can cause wheel bearing failure. If this happens at speed, a serious accident cannot be avoided.

- The vibration transmitted to the steering wheel causes increased driver fatigue. Reduces travel comfort, and on long run lengths it can lead to reduced traffic safety.

- If there is an imbalance, the tread rubber wears off quickly and unevenly. The service life of tires is reduced by 3-5 times.

The listed points are the most basic consequences of imbalanced wheels. But even this is enough to understand how important it is to promptly carry out work to restore the balance of the rim.

How to balance wheels

It is also worth considering how the adjustment is made. The parameter is leveled using weights that are attached to the wheel rim, or rather to its rim. There are the following types of weights.

- Printed. The simplest option. It is made of soft metal that can simply be stuffed onto the rim. Sticks well to the disc.

- Stickable. It is glued using a special adhesive tape. Typically used for rims that do not have the ability to mount stuffed balancers. The disadvantage is the risk of detachment at low temperatures or under a strong stream of water in a car wash.

To adjust the parameter, a special machine is required. Most often, a machine is used for rough adjustments. The master spins the wheel on the axle and, by placing a load, achieves the most even rotation. When performing the work, extensive specialist experience is required.

Precise balancing is performed on an electronic machine. This takes into account both the geometric parameters of the wheel and the tire. As a result, the stand computer calculates the exact placement and mass of the balancing weight. This type of work is the most accurate and virtually error-free.

Adjustments must be made on all wheels. A common mistake is to correct the imbalance only on the front axle. This can lead to destruction of the rear suspension and other negative consequences.

How often should wheels be balanced?

As was written above, according to the recommendations of car manufacturers, balancing is carried out after 10-15 thousand kilometers. It is usually combined with scheduled maintenance. It may also require adjustment if problems occur, or after any work on the suspension.

Knowing what balancing is and why it is needed, you can determine the adjustment time. By understanding the mechanisms that it uses, you can easily diagnose the need for this work. In general, maintaining optimal wheel balance has a very important impact on driving safety.

How to repair a tire yourself

How to remove and install wheel covers

Tire repair kit: when it comes in handy, composition, how to use

The difference between a tube tire and a tubeless tire - what is the difference?

Differences between radial and bias tires - design features

Tubeless tires - features, advantages, design

Treadwear - tire wear resistance index: what it is, what it affects

Run flat tires - features of the technology, for which cars they are suitable

Tire rolling resistance - what is it and what does it depend on?

Winter truck tires: types and features

Ecotires: features and advantages of economical tires

How to inflate a car tire with a compressor?

Running in winter studded tires - what is it, why is it needed?

How to choose car tires: what to look for

Wheel storage covers: types and selection rules

Types of winter tire studs - what they are: shapes and design

Rules for caring for tires: do tires require maintenance, why?

M/T tires - Mud Terrain: features and purpose of models

H/P tires - High Performance: features and purpose of models

Summer tire tread - types, features, what functions it performs

Balancing wheels in a car

The wheel balancing procedure is a recent one. Drivers neglect it because they do not know all the intricacies and advantages of the operation, remembering it only when the steering wheel begins to tremble and vibrate with every turn. The article talks about wheel balancing, what it is and why it needs to be done.

What is wheel balancing?

Wheel balancing is the procedure for preventing imbalance between wheels, rims, hubs, suspension parts and fasteners. The need for periodic operation is due to centrifugal force.

During the balancing process, the mass of the wheel is located evenly relative to its center. When the procedure is performed correctly, vibration during vehicle operation is reduced and the service life of bearings and car tires is increased.

Benefits of wheel balancing:

- Comfortable ride on roads of any type and quality.

- No unnecessary noise from car wheels.

- Increased wheel usage.

- Ease of driving at various speeds.

- Car tires wear out equally and evenly on all sides.

Wheel balancing is required for any car, regardless of the condition of the wheels, tires or the newness of the model.

Consequences of not balancing wheels:

- Frequent bearing failures.

- Steering wheel vibration during vehicle operation.

- Early and uneven wear of car tires.

- Noise in the cabin.

- Immediate shock absorber failure.

- Unsafe movement due to each wheel acquiring its own centrifugal force.

- In advanced cases, the vibration of the wheels causes the bolts to become unscrewed and the ball joint to fly out or fall off.

Why is the procedure necessary?

Inexperienced drivers doubt even after the given consequences of failure to balance the wheels, which can be the most unpredictable: from an uncomfortable ride to breakdown of the car’s chassis.

Driving a car at a speed of 90 km/h with size fourteen wheels out of balance by only 20 g is comparable to hitting part of the suspension with a sledgehammer weighing 3 kg. About eight hundred such strikes occur per minute.

Vibrations and beating of the steering wheel are one of the consequences of unbalanced wheels

Nobody forces you to balance your car, and there are no laws forcing you to do it, but you need to understand that it will cost much more to repair the car.

Imbalance and its types

Imbalance is the presence of unbalanced parts in a car that are in motion: hubs, drums and tires, which change the handling of the vehicle for the worse.

Improper balancing of one wheel causes imbalance. The center of gravity of the wheel must lie on the axis of rotation equidistant from the entire surface.

If this condition is not met, the wheel is considered unbalanced. It is important to remember that a wheel cannot be perfectly symmetrical, since production has its own errors.

Statistical imbalance is quite rare. It occurs when the axis of inertia and the axis of rotation are parallel. The mass is not distributed correctly along the entire axis of rotation. The center of gravity is shifted to one side, and the disk is over the entire surface. This imbalance is easy to notice: the car jumps at any speed, and it becomes impossible to steer. In such conditions, the suspension quickly breaks down.

Dynamic imbalance occurs more often than statistical imbalance. Owners of wide tires are more often susceptible to it. An imbalance occurs due to a mismatch between the axis of rotation and the axis of inertia. During vehicle operation, the center of gravity changes, which leads to dynamic imbalance. The car begins to throw in different directions at a speed of 40 km/h or more. The steering wheel begins to shake and hit my hands hard.

There are two types of wheel imbalance: static and dynamic.

The most common imbalance is a combination of dynamic and static imbalance. This situation is not critical. It can be easily corrected using a balancing machine. For discs that melt easily, it is better to use modern equipment using laser technology.

Procedure technology

Equipment

It is important to prepare the wheels for the balancing procedure, namely, thoroughly clean the tread and disk from sand and dirt. If this rule is neglected, the operation may be performed inaccurately and will have to be repeated. If the car has already been balanced, the technician must remove the balancing weights before starting.

It is very important to check the tire pressure: the tires should not be flat. Before balancing the wheels, the center of gravity is determined, which is monitored by balancing machines. Devices can range from ordinary computers to huge systems with laser sensors and measurement mechanisms. Once determined, the machine automatically installs the balancing weight.

To carry out the procedure, a balancing machine is used, which aligns the position of the wheel along the center of the rotation axis during the procedure.

The type of balancing weight depends on the type of discs. Weights with fastening brackets are installed on steel disks, and with landing on the inside - on cast disks. They are mainly made from zinc, lead or steel.

Weight also depends on the level of imbalance. The weight of the balancing weight with bracket fasteners varies from 5 to 100 g. The weight of the weight for alloy wheels is from 5 to 60 g.

The complexity of the procedure also depends on the mass. The larger the weight, the more likely it is that the wheel needs to be checked for its external qualities: tread condition and general geometric qualities such as symmetry.

In the cold season, due to temperature fluctuations, adhesive weights may come off, which cannot happen with padded ones.

There are special types of weights for stamped wheels. They are stuffed between the disk and the tire, installed on the edge of the disk. Padded weights are not suitable for low-fusible discs. For this type, there are Velcro - self-adhesive weighting agents with an adhesive base. They are practically invisible, because they practically do not stand out from the general appearance. However, they are used only on a perfectly flat surface.

The process of balancing car wheels

The procedure for balancing a car starts with removing the discs, regardless of the characteristics of the model. Balancing occurs according to the following method: remove the wheel, balance it, put it back, then move on to the next one. This completes the procedure for all wheels.

The result depends mostly on the artist, and only a small part is due to the equipment. If the device is modern, then the specialist can only monitor the condition of the rubber and the progress of the procedure.

After cleaning the tread from stones and dirt, a plate is selected, depending on the number of holes in the disc. The specialist places the plate on the disk, tightening the nuts well. After that, he goes to the machine to balance the wheel.

Before balancing, remove any dirt or stones from the tire tread.

After identifying the problem area, the process of installing weights begins. Upon completion, the master returns to the equipment and re-checks the geometric condition of the wheel. If the procedure is successful, the wheel is installed in its place and the next one is taken. Otherwise, the procedure is repeated.

Errors during the procedure

It happens that specialists make mistakes by performing the procedure incorrectly. Let's look at the most common mistakes:

- Neglecting the procedure for cleaning the wheel from stones, sand and dirt. In this case, it will not be possible to achieve an imbalance value close to zero.

- Carrying out the procedure on a damaged wheel.

- Installing weights on top of old ones.

- Insufficient tightening of nuts and bolts on the wheel.

Closely monitor the work of specialists. Even the most experienced workers make mistakes. At the end of the procedure, make sure that the balancing was successful.

Safety precautions

The most basic safety rules during surgery include:

- Wheel balancing can only be carried out by a specialist who has reached the age of eighteen, has passed a medical examination and received permission to perform work of this complexity.

- Wheels weighing more than 20 kg are transported on trolleys or other devices.

- Before the procedure, the condition of the wheel is checked.

- The workplace should be clean, not cluttered with parts.

- Work is not carried out by specialists under the influence of alcohol or drugs.

You should trust your car only to qualified technicians.

How to check wheel balance

It is convenient to check wheel balancing when the season changes. Those who store seasonal tires usually change them themselves, so it will not be difficult for them to check the balancing themselves. It is important that the wheels are clean. For the procedure you will need regular chalk.

- Spin the wheel.

- Wait until the wheel stops completely and scratch with chalk anywhere. For example, in the middle of the tire.

- Repeat the first two points five to ten times.

- Check where the marks are located. If they are close to each other, then balancing is required.

- Otherwise, everything is fine with the wheel and you can save on the procedure.

Is it possible to balance only the front wheels?

When balancing only the front wheels, the steering wheel stops vibrating, so many drivers feel that there is no need to balance the rear wheels. This opinion is completely wrong.

The rear wheels, no less than the front ones, receive mechanical damage when driving over uneven surfaces, so they also need to be balanced

Despite the fact that driving when balancing only the front wheels becomes much more pleasant, the problem does not go away. Unfortunately, parts and suspension wear out not only in the rear of the car.

How often should balancing be done?

According to the rules, balancing is carried out every 5000 km. In addition, balancing is carried out after a number of events:

- After every tire change: it doesn’t matter whether it’s seasonal or not.

- When the steering wheel vibrates.

- When colliding with a curb.

- When falling into a ditch or hole.

Timely balancing provides a guarantee for the long life of the suspension and tires, so take the procedure responsibly.