What does a maintenance-free battery mean?

Maintenance-free batteries

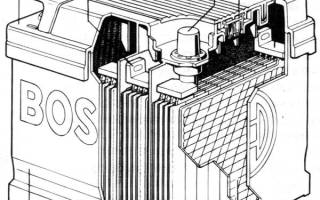

The term “maintenance-free” only means that batteries of this type do not require checking the electrolyte and periodically topping up during the entire period of their operation, but they should be recharged if necessary. The general structure of a maintenance-free battery is shown in the figure:

Rice.

Maintenance-free battery: 1 – one-piece cover; 2 – output cover; 3 – interelement connector; 4 – terminal; 5 – partition; 6 – plate jumper; 7 – body; 8 – lower installation guide; 9 – positive plates placed inside the separators; 10 – negative plates

Some batteries are sealed, but equipped with an outlet valve through which excess gases formed in emergency situations can escape and topping them up is generally impossible; in other batteries, the holes with plugs are preserved, so that in the event of unexpected gas release, water can be added to them.

Many modern battery models are equipped with a special indicator that allows you to quickly assess their condition. The principle of operation of the indicator is quite simple. A light guide is lowered into the electrolyte, to which is attached a box with a green plastic ball inside.

Rice.

Charge indicator: 1 – light guide; 2 – float; 3 – box

The density of the plastic is selected in such a way that when the density of the electrolyte increases, the ball floats close to the cut of the light guide, creating a green glow effect. When the battery is discharged, when the density of the electrolyte decreases, it sinks and the green glow disappears. Thus, the ball plays the role of a hydrometer - an indicator of the density of the electrolyte. In addition, the ball will go down when the electrolyte level in the battery drops critically.

Rice. How the charge indicator works

If the indicator is green, it indicates a full state of charge. When the indicator darkens and its color approaches black, the battery needs to be charged. If the indicator is colorless or yellow, this indicates a complete discharge of the battery and an unacceptable decrease in the electrolyte level and such a battery is discarded.

Maintenance-free batteries feature low-antimony lead fused grids to reduce gas generation and associated water loss during charging. This allows you to extend the life of the electrolyte and its testing, which is carried out every 25 months or 40 thousand km for maintenance-free batteries (according to DIN standards); Low maintenance and repair batteries are checked every 15 months or 25 thousand km.

For completely maintenance-free batteries (lead-calcium), the electrolyte level is not monitored. With the exception of two very small vent holes, this type of battery is completely sealed. As long as the electrical system is operating normally (u = const.), water decomposition is minimal and the electrolyte maintains its level above the active plates. This type of lead-calcium battery has the added benefit of limited self-discharge, making it best suited for storing energy for up to several months. A prerequisite for the operation of such a battery is precise regulation of the voltage at the output of the generator at a level of 14.4 V. When the charge voltage increases, gases will begin to be released from the electrolyte and this will lead to loss of water. If a maintenance-free battery is recharged using a non-vehicle charger, the charge voltage should never exceed 2.3...2.4 V per cell.

One of the problems with modern batteries is evaporation and leakage of electrolyte when the battery is damaged in the event of an accident. Some companies install flat gaskets in their batteries, located between the plates, the basis of which is fiberglass, absorbing the electrolyte, while all the edges of the plates remain dry. This helps prevent evaporation and leakage of electrolyte. Additionally, during battery charging, when the battery is close to full charge, oxygen begins to be released on the positive plates, whereas in conventional batteries, hydrogen begins to be released on the negative plates at the same time. The resulting oxygen passes through the separator onto the negative plates filled with lead sulfate and converts it into pure lead and acid. The potential of the negative plates does not reach the level at which hydrogen begins to be released, and therefore no water loss occurs. In addition, batteries of this design can withstand a significantly larger number of discharge-charge cycles, and their service life will be 8...12 years, depending on operating conditions. The cold start current increases by 70...90 A.

In order to conveniently monitor the technical condition of the battery, so as not to open the hood of the car, modern cars use various sources of information: light displays, sound signals and speech synthesizers that tell, for example, how many restarts can be made and after what time.

Which car battery is better: serviced or maintenance-free?

Today there are many types of batteries: acid and gel, calcium and hybrid, AGM and GEL models. But perhaps the most well-known division of batteries into classes is serviced and maintenance-free batteries. It was these two types of batteries that divided car enthusiasts into two opposing camps. Some advocate with both hands for serviceable models, while others “tear their vests on their chests”, protecting maintenance-free batteries. Is this really such a fundamental dispute, what is the difference between serviced and maintenance-free batteries and how to determine whether a battery is serviceable or not, we will now try to figure it out.

Serviceable batteries

As the name implies, serviceable batteries are those that can and should be serviced. In other words, you can unscrew one or more caps, look into the jar, see what is happening there, and, if necessary, perform certain actions. It was this possibility that led to the fact that experienced car enthusiasts, like hunters who make their own cartridges, not trusting “store-bought” analogues, zealously defend this type of battery.

On the one hand, they are right, and serviced batteries have a number of relative advantages:

- The ability to easily control the level and density of the electrolyte.

- Visual inspection of the condition of the battery plates.

- Timely detection of boiling during charging.

- Possibility to add distilled water or completely change the electrolyte.

In a word, you can periodically “pump” your battery, thereby extending its service life and improving its performance parameters. It would seem that this is a clear plus. But only on one side. What should those who don’t like to spend all their free time in the garage do and for whom the “ideal battery” is the one that “set it and forget it”? And to be honest, the need for maintenance is far from the only disadvantage of these batteries. Here are a number of other fairly significant shortcomings:

- Unsealed housing. The presence of removable covers does not allow the battery case to be completely sealed, which leads to boiling off of the liquid and, as a consequence, to a decrease in the electrolyte level. And if you do not notice this in time, the battery may fail, and without the possibility of recovery.

- Evaporation of water also leads to an increase in the percentage of sulfuric acid in the electrolyte, which has an extremely negative effect on the battery plates.

- In serviced batteries, the process of plate sulfation occurs much faster. Accordingly, you will have to desulfate the battery more often.

- Evaporation creates a specific white coating on the battery body, which, when accumulated, can even short-circuit the terminals, which leads to dire consequences.

- Well, and finally, you will have to look under the hood of your car much more often to check the fluid level in the battery.

Due to “numerous requests” from those who did not want to put up with these shortcomings, maintenance-free batteries were created.

Maintenance free batteries

The main advantage of these models is obvious - THEY DO NOT NEED TO BE MAINTAINED! Accordingly, they do not have removable lids on the jars. This, by the way, is the main sign that you should pay attention to when answering the question “How to distinguish a serviceable battery from a non-serviceable one?” Maintenance-free batteries are produced in cast, sealed cases, which, as you probably already guessed, allow you to avoid most of the problems described in the previous section.

When boiling, the electrolyte does not evaporate, but settles on the inner walls of the battery, after which it is safely returned to the jars. Thus, the liquid level remains practically unchanged. In other words, you can forget about checking the battery condition and reduce the number of “dives” under the hood to a minimum. Agree, great! Especially for novice car enthusiasts.

But don’t fall into premature euphoria - maintenance-free batteries also have disadvantages.

Firstly, you cannot control the internal state of the battery, namely the color of the electrolyte. What if, due to the shedding of the plates, it turned black? How do you think this will affect battery performance? That's right, negative. True, some models of maintenance-free batteries are produced with a transparent case, so this problem can still be solved.

But what about “ringing” the cans to determine which of them is not working for one reason or another? Or with measuring electrolyte density? Unfortunately, neither the first nor the second can be done with maintenance-free batteries.

In addition, such batteries are equipped with a valve that protects the battery from overcharging. On the one hand, this is a wonderful solution - if the charge level is significantly exceeded, steam will escape through the valve to the outside and the battery will not explode. But on the other hand, several such “emergency emissions” and the electrolyte level will drop significantly. But you won’t have any opportunity to top it up again.

So, although maintenance-free batteries require much less attention from the owner, you still have to keep an eye on them, at least with one eye.

Service life of maintained and unattended batteries

But how do you decide which battery is better - serviced or maintenance-free and which battery to choose for your car?

There is one factor that tips the scales towards one of the options. This is the resource, or, in other words, the battery life. And we can absolutely unequivocally say that for maintenance-free models it is noticeably higher. Of course, if you at least minimally adhere to the rules of battery operation.

So, if you are faced with a choice of which battery to purchase, we recommend that you pay attention to maintenance-free models. This will not be difficult to do, since more than 70% of the batteries that are present in the assortment of car dealerships today are just like this. And finally, one more banal piece of advice: choose a battery from a well-known, trusted brand and you can be sure that it will faithfully serve you for the entire prescribed period.

How to maintain a maintenance-free car battery

The development of electrical energy storage systems using chemical processes helps create truly useful maintenance-free devices, thereby significantly simplifying the life of motorists. On the other hand, the slightest innovation in battery design is immediately used by companies selling car batteries to effectively present the undeniable advantages of their products.

From advertising slogans, new battery designs looked like they did not require human intervention for normal operation. A more than attractive offer, especially if a person already has negative experience with servicing and charging batteries.

What does a maintenance-free battery mean?

The main task in servicing batteries of classical design was to maintain the specified density and electrolyte level. High temperature and overcharging forced periodic replenishment of water losses in the battery banks. The first maintenance-free batteries appeared in the United States in the early 1980s. Thanks to the use of an alloy with a calcium content of up to 0.1% and tin up to 0.12% for the fittings of electrodes and jumpers instead of lead, it was possible to significantly, almost six to seven times, reduce the intensity of gas evolution and self-discharge. Water losses were small and did not require replenishment for more than two years. The market has dubbed such structures “maintenance-free.”

Modern designs of maintenance-free batteries appeared on the markets of the USA and Western European countries in the late 90s. After numerous experiments, a multicomponent high-purity alloy was developed, which already contained additives of silver, aluminum, calcium, tin, and antimony.

Such batteries began to be positioned in sales as maintenance-free. They purchased:

- sealed enclosures,

- special separators and lead sludge traps,

- Holes for monitoring electrolyte and adding water have been removed from the design.

For some time, even the formulation of the problem - how to add water to a maintenance-free battery - disappeared; its losses were reduced to almost zero.

Despite some optimism, the question of how to maintain a maintenance-free battery has become more complex and requires higher quality chargers. The battery presented new, but feasible operating conditions. The main condition is a constant voltage of high stabilization, deviation from the optimal parameters is no more than 0.1 V. This is the only way to ensure the guaranteed service life of a maintenance-free car battery and its reliability. The stability of the charging system of a generator or stationary device is created by electronic control systems.

On machines of old designs with a high degree of wear and tear on engine components and assemblies, the use of a maintenance-free battery will require the installation of modern generators with microprocessor control of charging voltage and current. In this case, it is worth thinking about which battery is better to use - serviced or maintenance-free.

Disadvantages of using maintenance-free batteries

One of the world's leading manufacturers of maintenance-free batteries, VARTA Geraetebatterie GmbH and Robert Bosch GmbH corporations, position their products as an improved product with a discharge current increased by 30%, and a guaranteed pre-sale storage period of up to 18 months. Admittedly, German and European factories do indeed produce maintenance-free batteries of the highest quality.

High discharge parameters allow the use of lighter and more compact batteries for cars than the standard 45 and 55 Ah for gasoline engines of class “B” and “C” cars. The ability to complete car lots for export to third countries with maintenance-free batteries makes it possible to simplify the supply of cars placed in the warehouse.

In real operating conditions, high sensitivity to incomplete charge and deep discharge, especially at subzero temperatures, makes maintenance-free batteries vulnerable. Two or three short-distance runs with an undercharged battery in frosty winter weather, long-term parking in the open air, and perhaps there will not be enough charge to subsequently start a frozen engine. And for the battery itself, such a load will be fatal; you will have to look for a way to restore a maintenance-free car battery.

At low temperatures, the viscosity of the electrolyte increases and the rate of diffusion of ions in the active mass decreases. During a starter discharge, local heating areas appear on the surface of the electrodes, from which the bulk of the energy is removed. During the process of temperature recovery, such spots are sulfated faster and more intensely than other areas of the electrode.

For objective reasons, the acid concentration in the electrolyte cannot be higher than 1.3 g/cm3. As the amount of sulfuric acid increases, the potential capacity of the positive electrode increases, and that of the negative electrode decreases due to a decrease in the rate of reactions on lead. The optimal level of electrolyte density is determined taking into account the operating conditions and battery load. For serviceable batteries of the old design, there were instructions according to which the concentration of H2SO4 in the electrolyte was adjusted by adding water or acid from 1.22 to 1.28 g/cm3, depending on the operating temperature. To optimize the electrolyte density in a maintenance-free battery, it is necessary to use correction tables for acid content.

How to check the electrolyte level in a maintenance-free battery? For these purposes, the manufacturer uses a window insert made of transparent plastic, which allows an objective assessment of the electrolyte level, or the battery case is made of translucent material, through which the levels in all banks are clearly visible.

Sooner or later, the characteristics of the battery will no longer satisfy the owner, and the question will arise about the advisability of purchasing a new one or repairing a maintenance-free battery.

The battery is diagnosed after carrying out several reference control and training cycles: The last charge is carried out with a current of 7-8A, not allowing the recommended voltage to be exceeded. Immediately after charging, check the voltage at the battery terminals using a special load plug or record the exact reading of a multimeter.

The load plug records the voltage drop across the terminals under a reference load; it can be used to check the charge of a maintenance-free car battery.

If intense gas evolution begins during charging, it may be necessary to adjust the electrolyte composition by adding water. How to add water to a maintenance-free battery - you can use a syringe, as in the video:

Repairing maintenance-free batteries is in many ways only possible if you have the skills and equipment, but in 90 cases out of 100, repairs are limited to:

- carrying out desulfation of battery plates, including using Trilon-B or other special chemicals;

- repeated charging and discharging with very small currents on an electrolyte of low density;

- gluing or welding cracks in the battery case;

- repair of terminals.

A more complex level of repair is limited by the need to decide how to open a maintenance-free battery. Typically, the upper front cover of the battery is made of polypropylene and is “hot” pressed onto the base. Any heating of the case in order to remove the cover causes deformation, and subsequent attempts to replace it will not be successful. There are options when the cover snaps into the lock of the battery case using rubber gaskets.

In this case, you can remove the cover if you find the corresponding groove on the end surface and carefully pry it off with a flat screwdriver as in the video:

Which battery is better, serviced or maintenance-free, the answer is that a product of higher quality that has proven itself in practice will win. Maintenance and care must be provided for both types of batteries.

Maintenance-free battery, how to service you?

Maintenance-free battery, how to service you?

Advice from professionals at the Battery House in St. Petersburg

Obviously, no one is interested in extra hassle with a car. For this reason, many motorists, including professionals, install so-called maintenance-free acid batteries using the “set it and forget it” principle.

In this article we will talk about the pros and cons of a maintenance-free acid battery, how maintenance-free it really is, and how to operate it correctly.

First, let's define what a maintenance-free acid battery is and what it looks like externally.

Immediately pay attention to the presence of plugs for access to the electrolyte. If there are no traffic jams, then it is a maintenance-free battery.

But this sign is optional. Looking ahead, let's say that good batteries have plugs.

How to understand whether the battery in front of you is being serviced or not

Sometimes the battery may say maintenance-free in English .

calcium-calcium or Ca-Ca technology may be indicated . Don’t worry, we won’t delve too far into electrochemistry; just remember the name of the “calcium-calcium” technology.

Why is such a device considered maintenance-free, and how does this lack of maintenance manifest itself?

As the name suggests, the electrolyte in such a battery is acidic, in a liquid state. And liquids tend to evaporate. More precisely, water evaporates from the electrolyte.

Modern technologies make it possible to create batteries in which this evaporation is minimal.

Therefore, such batteries do not require topping up with distilled water throughout their entire service life..

As you understand, it is for this reason that such batteries may not have plugs.

You will be surprised, but the lack of maintenance comes down solely to the fact that the owner does not need to monitor the electrolyte level. However, this is a serious plus of a maintenance-free acid battery.

The next advantage, which is directly related to the calcium-calcium technology, is low self-discharge. What does this mean for the owner?

Over a fairly long period of time, for example, a month, while you are on vacation and do not use the car, the battery will practically not lose charge. If, of course, you turned it off, you removed the terminals from it. Then, returning from the resort, you will get into the car, turn the ignition key and drive calmly.

Pros of maintenance-free batteries

Another positive aspect of such batteries is the increased starting current. In practice, this means that a smaller battery will be able to start a heavier engine.

So, the advantages:

- there is no work with electrolyte;

— low self-discharge;

— increased starting current;

Now let's talk about the disadvantages that a maintenance-free acid battery has.

Disadvantages of maintenance-free batteries

THE FIRST minus is that these batteries are afraid of deep discharges.

What does this mean for the owner? When the engine does not start the first time, but you have to make several attempts, it is quite possible that during the next attempt the battery simply will not have enough energy to start. Or when the on-board network consumes more energy than the generator can produce. This option can also lead to a deep discharge. And a deep discharge is practically a failure of the battery, since it is very difficult to remove a battery made using the “calcium-calcium” technology (do you already remember this name?) from a state of deep discharge.

Now attention! Now there will be an amazing discovery for many: maintenance-free batteries REQUIRE charging! Yes, yes, this is not a mistake! Maintenance free batteries REQUIRE charging.

If you want your battery to last a long time, you will have to REGULARLY monitor the battery's charge level, and if there are plugs, the density of the electrolyte.

And twice a year - before the winter season and after it - perform a regular (normal) charge of the battery. Otherwise, the battery may work with systematic undercharging, which will lead to its failure.

We talked about systematic undercharging and deep discharge. A detailed story about these troubles is in our educational video “How to extend the “life” of your battery.” In addition, you can glean some information from our other educational video “Change or charge?” Text versions of both of these videos are presented in the “Blog” section, in materials with the same names.

Below we will give clear instructions on how to properly charge a calcium-calcium battery.

The second disadvantage of the calcium-calcium technology battery is that it is very difficult to charge!

Let’s make a reservation right away: as long as the battery is regularly and fully recharged, there are no problems. But, as soon as the battery’s condition approaches critical (to a state of deep discharge), the same difficulties begin. But there is no way to detect a deep discharge in advance - only after the fact. That is, the car simply did not start. Doesn't sound too cheerful, does it?

So about the difficulties.

Let's start with the fact that the final charge voltage for this type of battery should be in the range from 15.0V to 16.5V. The exact voltage value is determined by the ligating components in the battery chemistry and the charging temperature.

A standard generator will not always be able to produce such a voltage - usually its value is limited to 14.4V, and more often lower.

And this is an almost guaranteed undercharge!

Yes, we can already hear the smartest people saying: “So you just need to raise the generator voltage by turning the relay setting!” Even if this can be done, such an adjustment will not be a panacea. And then you will understand why.

So for now, just remember that it is impossible to remove the battery from a critical state using a GENERATOR.

There remains the option of recharging with a charger.

The charger must not only produce a voltage above 15 Volts, it must be able to control the charge current, gradually reducing it. Let's face it - such smart devices are very rare. So if the automation of your charger does not know how to do this, then you will have to change the settings manually. Just keep in mind that charging the battery does not take five minutes, or even an hour.

The MINIMUM time for bringing a battery out of a critical state is DAYS!

And in especially severe cases, up to three days! Are you ready to watch the battery for three days, checking the charge parameters every 2-4 hours? After all, the charging process cannot be interrupted! Now do you understand that no amount of alternator voltage adjustment will solve anything?

Below we provide an approximate graph of the charge of a calcium-calcium battery. It is impossible to indicate exact voltage values, since it depends on the ligating additives of a particular manufacturer. In addition, the speed of the process will depend on temperature. We provide voltage values for a temperature of 20 degrees Celsius.

For simplicity of current calculation and greater clarity, we will assume that the battery capacity is 100 Ampere-hours.

So, the first step.

We set the final voltage limit to 14.6V – 14.8V, and set the current to 7% of the capacity. For a capacity of 100 Amp-hours this is 7 Amps.

If the charger is programmable, then it will automatically switch the charge to the next stage. If everything is done by hand, then you need to monitor the voltmeter, and when it shows a voltage of 14.6V - 14.8V, switch the charger to the second stage.

Please note that time in this case is secondary and depends only on the degree of battery discharge. That is, the only parameter by which we can judge the end of the first stage of charging is whether the battery reaches the specified final voltage. The same principle will apply to the second stage.

Second stage

We set the final voltage to 15.0V – 15.2V, current 3% of the nominal value. In our case, 3 Amperes. And we also don’t pay attention to time, we wait for the specified voltage to be achieved if we do everything ourselves. Or we trust the charger program.

Third stage

We set the final voltage to 15.2V – 16.0V, current 1% of the nominal value. In our case, 1 Ampere.

But the third stage should last at least 10 hours.

After that we wait a day.

Now you need to measure the voltage with a load fork without load and under load. And for batteries with plugs, also measure the density of the electrolyte.

For a fully charged battery, the voltage without load should be at least 12.8V, and under load - at least 10.8V.

Electrolyte density is 1.27-1.28 g/cm³.

Please note that such a three-stage charge for calcium-calcium batteries is used both for normal charging and for removal from deep discharge. The only difference is that a normal charge will take 10-14 hours, but recovery from a deep discharge, as we said, can last up to three days.

And, of course, you can’t do this with the first charger you come across.

Well, how? Do you still believe in battery maintenance-free?

So, the main recommendation for a calcium-calcium battery is:

REGULARLY MONITOR THE CHARGE AND DO NOT ALLOW DEEP DISCHARGE!

Let us remind you once again that for more complete information, watch our videos “How to extend the “life” of the battery” and “Change or charge?”.

Text versions of all videos are presented in the “Blog” section, in materials with the same names.

Specialists from the Battery House company were with you.

What is a maintenance-free battery and how to maintain it

The term “maintenance-free batteries” appeared with a significant change in the production technology of lead-acid batteries. Classic batteries have the following disadvantages:

- The presence of antimony additive in the electrodes improves strength and casting properties, but increases the tendency to gas formation at high charging currents.

- The need for regular monitoring of the electrolyte level and density.

- High self-discharge value.

- Risk of shedding of the active mass of the electrodes.

Replacing antimony in the alloy with calcium and other metals helped reduce the negative qualities. Maintenance-free calcium batteries do not require regular monitoring, but they have a number of disadvantages:

- The stability of the onboard voltage must be high (no more than 0.1V).

- Deep discharge of the battery is not allowed.

- It is difficult to control the state of the electrolyte.

Based on the above, it is sometimes difficult to choose a serviced or maintenance-free battery for your car.

Maintenance-free car battery design

There are no fundamental differences in the designs of lead-acid batteries. Only the production technology differs. Maintenance-free batteries are made from materials of high purity with a change in the composition of the alloy of the electrode plates.

Thanks to the fact that it was possible to reduce gas emission (electrolytic decomposition of electrolyte water), it became possible to seal the battery case. As a result:

- there are no losses due to water evaporation;

- surface self-discharge reduced to a minimum

- additional cavities under the electrodes prevent falling sludge from short-circuiting the plates.

Flaws

The most significant drawback inherent in maintenance-free batteries is the high requirements for the stability of the on-board network voltage. This requirement is a consequence of the fact that calcium batteries do not allow deep discharge, thereby losing their capacity.

Systematic undercharging during short trips in winter leads to the fact that after a number of successive starts of the starter, the EMF level approaches the minimum permissible, and the generator voltage is reduced due to the large number of consumers (heated mirrors and seats, headlights, heater operation). Before installing a maintenance-free battery in a car, you should make sure that the generator has the necessary power reserve and that the stability of the on-board network voltage does not go beyond the specified limits.

Even worse for such batteries is high voltage. Towards the end of the charge, no matter what quality the batteries have, the moment of electrolysis of water in the electrolyte comes. In a sealed case of maintenance-free batteries, this can lead to swelling of the case, cracks, and leakage of electrolyte.

Which is better, a regular battery or a maintenance-free one?

If the car meets the listed requirements, then the answer is clear, the new calcium battery is much better. Such batteries relieve the car owner of some of the responsibilities and improve the reliability of starting the car.

Another thing is a car with an outdated on-board power supply system. Old domestic and foreign models with a relay voltage regulation system do not provide the necessary stabilization of the charge current at the battery terminals. As a result, either undercharging or overcharging occurs with all the ensuing consequences. Servicing new batteries is difficult or impossible. At the same time, batteries often do not even fulfill their warranty period.

Maintaining a Maintenance Free Battery

To quickly monitor the condition of maintenance-free batteries, manufacturers equip them with a special indicator, which can be used to approximately estimate the degree of charge and electrolyte level.

Attention! By the presence of an indicator (eye), you can distinguish a maintenance-free battery from a regular one.

It is important to know that the indicator displays the status of only one of the cans, mainly the central one. What happens in the remaining ones is unknown. If the indicator shows a low charge level, the battery must be recharged using a charger with good stability of output voltage and charging current.

The only accessible and reliable method for checking a maintenance-free battery is to measure the EMF with a load fork. Simply measuring voltage with a voltmeter does not provide the necessary accuracy, since it does not take into account the internal resistance of the battery. In the load plug, a load of high-resistance wire is connected in parallel to the terminals of the voltmeter. The load resistance corresponds to the rated discharge current of the battery.

A reduced voltage level with normal indicator readings indicates a malfunction in one of the cans.

Most conventional electrolyte monitoring methods void the product warranty because the sealed housing prevents access to the battery cells to determine their condition.

Adding water or electrolyte

In order to add water to a maintenance-free battery or measure the electrolyte density, you need to gain access to individual banks. Some manufacturers cover the caps of the jars with a decorative lid. In essence, such batteries are no different in design from classic, maintenance-free ones, and normal maintenance methods are applicable to them. If the cover is glued, it can be carefully removed from the body and then glued again.

It’s worse if the lid is welded monolithically to the body. In this case, opening a maintenance-free battery is much more difficult. You can make holes opposite the filler necks. After servicing, the holes are closed with hermetically sealed suitable caps.

Attention! When drilling holes, it is important to prevent chips from getting into the electrolyte. To do this, pre-drill holes with a drill of a smaller diameter.

It is safer to use a large volume syringe. When using a syringe, the diameter of the holes does not exceed 1 mm. In order to determine the electrolyte level, the syringe needle is gradually lowered into the hole, while simultaneously extending the rod. When electrolyte begins to be sucked into the needle, mark the level on the needle. The same actions are performed for all battery jars.

To check the density, part of the electrolyte is drawn into a syringe and poured into a suitable container, from which it is convenient to draw for measuring the density with a hydrometer. We must remember to return the tested electrolyte to the same jar from which it was removed.

When the electrolyte level is low, distilled water is poured into the jars, and in the case when it is necessary to increase the density, for example, when switching to winter mode, then a correction electrolyte with a density of 1.4 g/cm3 is added. In this case, it may be necessary to select part of the electrolyte so that the final level does not exceed the permissible level.

After manipulating the electrolyte, the battery is charged in order to naturally mix the liquid medium. Turning the battery over to drain the electrolyte or mix it is strictly prohibited, as the electrodes will short-circuit with the crumbling sludge.

The containers in which the electrolyte will be located must be made of glass, ceramics or plastic. The use of metal utensils is not allowed, since the electrolyte is a chemically active medium and reacts with most metals. The stainless steel from which the syringe needle is made is an exception.

Battery recovery

If necessary, you can try to restore both regular and maintenance-free batteries, since they have the same faults. The loss of capacity and uneven change in density in individual banks is restored in maintenance-free batteries through several cycles of charge and discharge with rated currents. Such actions help to dissolve large crystals of lead sulfate, which reduce the amount of active substance necessary for the chemical reaction to occur.

Gel batteries

Batteries in which the electrolyte is condensed to a jelly state stand apart. Such batteries are highly reliable due to the low fluidity of the electrolyte, can withstand lower temperatures, but are even more critical to the stability of the on-board voltage and have a high cost.

Important! Repairing maintenance-free gel batteries with your own hands is almost impossible and impractical.

Conclusion

It is impossible to say for sure which battery is better maintained or maintenance-free, and in which car a maintenance-free battery can be installed. It depends on many factors. Under favorable conditions and compliance with all requirements, the service life of calcium batteries is at least 5-7 years, which is slightly higher than that of conventional ones.